What are filming amines?

Filming-amines based chemicals for water treatment are organic blends of film-forming amines, neutralizing amines and polymers, used in the industrial field to fight corrosion and scale accumulation inside steam generators, boilers, closed loops or cooling systems.

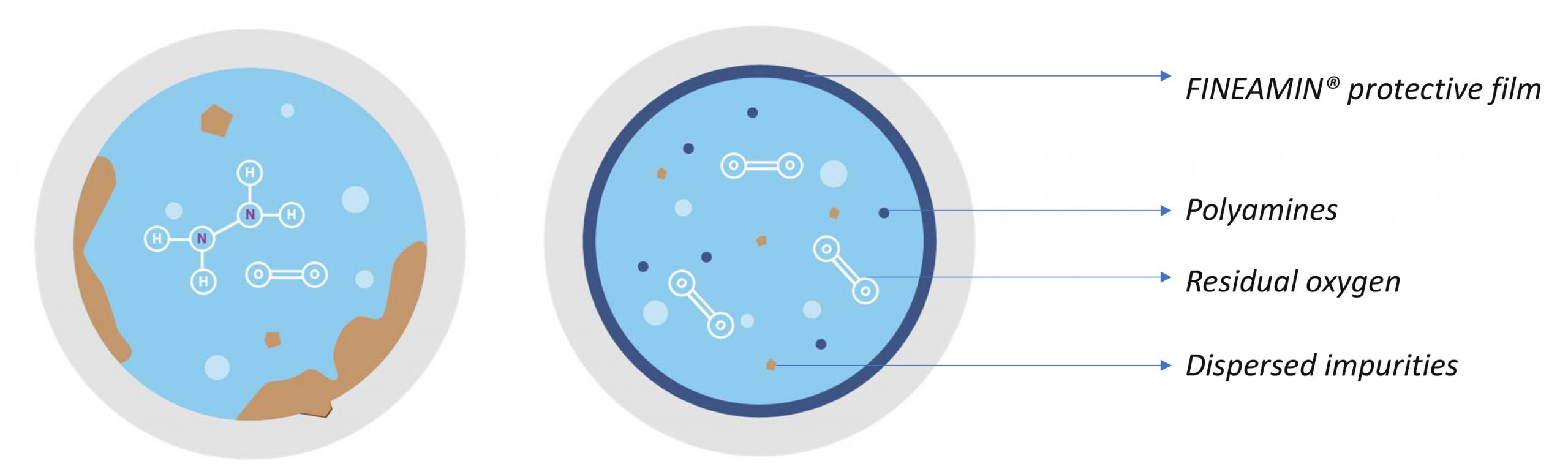

Filming amines (polyamines) technology represents an alternative to conventional water treatment methods, a feasible and more environmentally friendly hydrazine substitute. It consists of series of organic, surface-active corrosion and scale inhibitors continuously dosed in the feed water, having the unique ability of forming a a microscopic, hydrophobic film on all the metallic surfaces thorough out the whole system – a homogeneous barrier between water and pipes. The active polyamines contained in the formulations are naturally connecting to loose nitrogen atoms present in the metal. This prevents oxygen to attack the metallic surfaces, while at the same time improving the heat transfer. And since the amines are volatile, they protect the whole system, not only the area where the oxygen scavenger is injected.

Using our unique FINEAMIN® solution, we replace toxic hydrazine and phosphates, which are toxic for the people who work with those substances and not environmentally friendly.

About the FINEAMIN® brand

FINEAMIN® products are continuously developed based on a 30 years research and experience in organic industrial water treatment. For the last 15 years, our products have been sold worldwide under the Swiss FINEAMIN® brand.

Superior in quality and formulation to usual FFA programs, FINEAMIN® water treatment chemicals are highly-efficient, proprietary substances combining film-forming amines, neutralizing amines and polymers, as well as other harmless components.

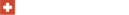

Before FINEAMIN® polyamines

After using FINEAMIN®

FINEAMIN® (filming amines) Water Treatment Mechanism

FINEAMIN® chemicals are special polyamines (also known as filming amines) and polymers mixtures, developed based on a high-end SWISS formula and delivered as “all-in-one” products that prevent the formation of deposits and fight against corrosion inside steam generators, cooling towers and district heating systems. Still, the main role in each FINEAMIN® blend is held by the hydrophobic, surface active, film-forming amines. These, along with polycarboxylates meant to disperse new and existing deposits and alkalizing, volatile amines, travel through the whole system building a monomolecular barrier (an almost invisible film) between water and metal surfaces.

These components found in FINEAMIN® organic water treatment chemicals provide optimum protection and passivation of all ferous and non-ferous metal surfaces along the water-steam- condensate cycle. They decompose and act inside systems highly related to the vairous temperatures along the circuit:

- pH control in feed water, boiler water and condensate by means of Neutralizing Amines;

- Corrosion protection of the feed tank, the boiler and the condensate lines by means of Film Forming Amines;

- Dispersion of scale-forming salts by using Polymers.

Each FINEAMIN® blend is a multifunctional corrosion and scale inhibitor meant to clean and protect. Through the affinity of the special polyamines of FINEAMIN®, a metal surface is isolated by means of the hydrophobic layer. NO new deposits! NO contact with residual oxygen.

Different from usual amines water treatment program, the polyamines from FINEAMIN® products adhere differently to the metal surface. Due to the existence of a large number of amino groups in the mixture, the bonding to the metal surface takes place in various points and it is obviously extremely strong. The carbon chains are directed mostly horizontal and so they allow a better cohesive protection.

The protective film that results is stable and continuous, and offers a good protection against corrosion. Calcium and iron salts that usually are cleaned by purging, are easily cleaned on-line with FINEAMIN®. The film formed by the filming amines prevents, for example, the development of calcium carbonate crystals, especially in heat transfer areas, by keeping the contaminants suspended in order to help the other FINEAMIN® components to disperse them.

FINEAMIN® filming amine corrosion inhibitors do not need oxygen scavenger to protect the water circuits. They fully protect the system against dissolved oxygen corrosion and residual salts in boiler systems equipped with thermal deaerator and are efficient for cooling towers, as part of a more complex cooling systems treatment program. Oxygen measurement is not needed anymore.

For the peace of mind of our clients, we do have products that contain a small quantity of organic oxygen scavenger, upon request.

Filming Amines Benefits

Compared to old ways of water treatment, filming amines (polyamines) improve greatly the operational process in any facility, especially in steam generators plants, by reducing the overall costs of production and functioning while keeping a safe working environment. For more a more detailed description of the benefits obtained by using SWISS film-forming amines, please read: FINEAMIN advantages.

Easy dosage and handling

One dosage point, using the same equipment as for the previous, conventional water treatment chemicals.

Full water-steam cycle protection

Polyamines dual mode of action manifested, on one side, through the adsorption on the metal surface, while neutralizing water contaminants, on the other side, protects effectively the entire steam generating system.

Reduced Operational Costs

Maintenance costs decrease as the film formed on the pipes protects against corrosion, preventing breakage and leaks. By acting on the magnetite layer, the heat transfer is improved, reducing excess energy consumption. Blowdown is also reduced, resulting in lower water consumption.

Environment Friendly Chemistry

70%-80% biodegradable, being compliant with international guidelines on environmental safety.

Convenience

The polyamines water treatment program is extremely convenient, simplifying the operation by replacing multiple chemicals with only one film-forming product.

Durable Reliability & Availability

Fast dosing along with ability of building a protective barrier on the pipes gives long term reliability. Amines travel throughout the water and return with the steam. Continuous protection, less shutdowns.

Filming Amines for Boilers

FINEAMIN® focuses mainly on boiler water treatment. Our boiler additive range of chemicals based on filming amines differs depending on the application parameters and can be tailored according to end-user’s necessities.

One of the main products is Fineamin 06, used for low and medium pressure boilers (<120 bar) in power plants, incineration plants, wood factories, food production, hospitals, malls.

Alternatively, Fineamin 90 is the version used for high pressure and high temperature boilers. Fineamin 90 can be used with brands like Benson, Babcock and Wilcox, being OEM compliant for operating pressures up to 220 bar and temperatures up to 540°C.

Last, but not least is Fineamin 39F, NSF-accredited and FDA-compliant filming-amine mixture, especially developed for food industry boilers, where steam goes into contact with the final product.

Filming Amines for Cooling Systems

For cooling water, FINEAMIN® manufactures both traditional, and hybrid solutions.

Traditional treatment chemicals for open evaporative cooling towers are Fineamin 91 and Fineamin 92 (for corrosive waters) both based on phosphonates and polymers. Along with them, we often supply additional dispersant, plus non-oxidizing biocides such as Finealga 25 and Finealga ME.

Meanwhile, hybrid treatment for cooling towers includes Fineamin 47 – filming amines based mixture for corrosive water like RO or softened make up water, and Fineamin 47 T – filming amines based mixture with phosphonates for scaling waters.

For closes circuits, instead of nitrite or molybdate based chemistry, we are using film forming amines base technology like Fineamin 06 (big systems), Fineamin 29 (copper and copper alloys), and others.

Custom Water Treatment Solutions

FINEAMIN®‘s custom programs, centered around the innovative use of filming amines, are designed to cater specifically to the unique demands of various water systems.

As the requirements of each system can significantly differ based on factors such as the application, equipment age, and frequency of use, FINEAMIN®‘s approach is to tailor a solution that aligns perfectly with these needs, with your system’s needs. Our water treatment programs aim to enhance equipment longevity, foster significant savings on fuel and water expenses, and ensure the sustained optimal performance of your operations.

Contact us and learn how our custom programs can transform your water treatment strategy.