Boiler Water Treatment

Steam generating industries portray the majority of our FINEAMIN® – filming amine-based chemicals range users, either we talk about high pressure or low pressure boilers, drum type or once though units.

Boiler water treatment / chemical conditioning and metal pipes protection are mandatory for improved operation in power plants, refineries, wood industry, sugar mills, papers mills, food industry, waste incineration and more. Given the circumstances, our film-forming amines are up to the challenge of ensuring highest performance of any industrial boiler in your plant, even if we speak about alkaline boil out or boiler preservation.

Film-forming amines based treatment is an alternative to conventional anticorrosion water treatment methods. Its action is manifested through the creation of a microscopic, hydrophobic film on the metallic surface, by using polyamines, which are naturally connecting to loose nitrogen atoms present in the metal.

This prevents oxygen to attack the metallic surfaces, while improving the heat transfer. And since the amines are volatile, they protect the whole system, not only the area where the oxygen scavenger is injected.

For an improved action and depending on the state of the plant and current chemical regime, FINEAMIN formulations may contain various dispersants, alkalizing and neutralising amine blends.

Applying our unique FINEAMIN anticorrosion and antiscale solutions, you have the opportunity to replace toxic and hazardous products like hydrazine considered to be carcinogenic and phosphates which are not environmentally friendly.

Over and above these safety and environmental benefits, using FINEAMIN typically protects the whole water-steam cycle and reduces the quantity of blow-down (as there are no solids to dispose of), improves heat transfer because of a better magnetite layer, thus reducing energy needs.

Using and storing FINEAMIN chemicals is extremely easy, as they do not impose any speial measures for workers or warehouse.

FINEAMIN products come as “all-in-one” mixtures – one product with multiple components that decompose according to temperatures, along the system, offering unparalleled protection in the exact place.

In 99% of the facilities using FINEAMIN products, the dosage is made through only ONE point.

Recently, two research studies have been conducted by ICEMENERG – National Institute for Research and Development in Energy in Romania. The studies discuss the influence of polyamines in water steam circuits for a power plant and a fertilizer plant, with high and medium pressure boilers. Reference: IEEE.

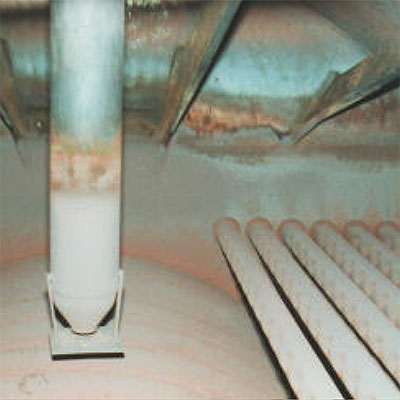

Before FINEAMIN®

- Existing corrosion & deposits

- Uneven magnetite layer

- Pipe leaks due to flow accelerated corrosion

After FINEAMIN®

- Reduced corrosion on all metal parts

- Evenly distributed magnetite layer with improved structure

- Reduction in pipe wall thinning

FINEAMIN® recommended products for water-steam cycles: FINEAMIN® 06, FINEAMIN® 90, FINEAMIN® 24, FINEAMIN® 88, FINEAMIN® 39

Our custom-made boiler water treatment chemicals and programs increase the efficiency and the economic viability. Any water management plan concerning the chemical regime of the plant will be established ONLY with our specialists and depending on the plant parameters (steam tons/hour, pressure, etc).

Your System Parameters Form

To be able to find together the best solution for boiler water treatment in your facility, please fill in the following STEAM questionnaire and send it by e-mail at the e-mail address specified on our Contact page.