| Test Details | |

|---|---|

| Product | FINEAMIN 06 | Samples | raw steel pipes | Sample 1 | 500ml demin water | Sample 2 | 500ml demin water & polyamines | Test period | 14 days | Test conditions | no additional water/ product | Test objective | product stability |

About the filming amines test

Film-forming amines, used as corrosion inhibitors for boiler water treatment, are, nowadays, one of the best alternatives for hydrazine replacement.

As we are all aware, a proper chemical conditioning of the water used inside industrial steam generators prevents corrosion and deposits, maintaining a safe and economical operation of the plant, even through out long conservation periods. The corrosion process and the transport of the corrosion products through the system are strongly connected to the metallurgy and its exposure to water carryover and dissolved oxygen.

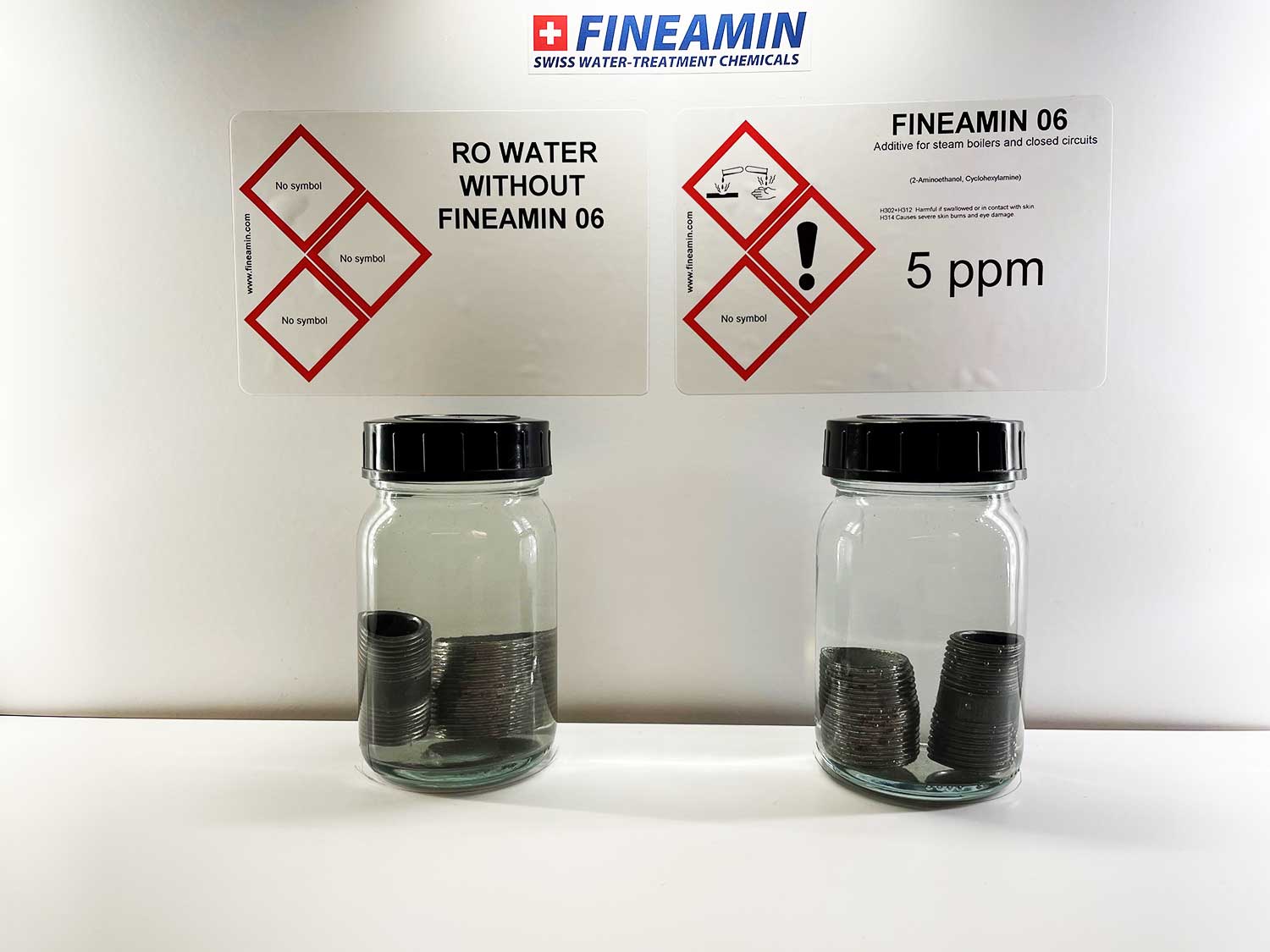

In order to emphasize the importance of a thoughtful water treatment and the capabilities of filming amines in protecting metal surfaces, a simple, short-term test was made in the Geneva manufacturing facilities by submerging raw steel piping in demineralized water and FINEAMIN 06 over a period of 14 days.

| Contents | Sample 1 | Sample 2 |

|---|---|---|

| Demineralized water - 500 ml | YES | YES |

| Raw steel piping | YES | YES |

| Polyamines & polymers mixture - 5ppm | NO | YES |

| Oxygen scavenger | NO | NO |

FINEAMIN 06 is a boiler water additive based on filming amines and used as primary corrosion and scale inhibitor. Its formulation consists of a mixture of volatile, long chain film forming polyamines and cleaning polymers. By continuous dosage to the feed water, the product adheres to the metal surface forming a stable, protective barrier against water residues, especially oxygen. FINEAMIN 06 has been successfully implemented worldwide in numerous water-steam-condensate cycles, in particular, in power plants.

The objective of the 2 weeks long laboratory study is observing the evolution of the corrosion as well as proving the immediate effect of FINEAMIN 06 against residual oxygen: its filming abilities and its stability as a solution for protecting the metal surfaces.

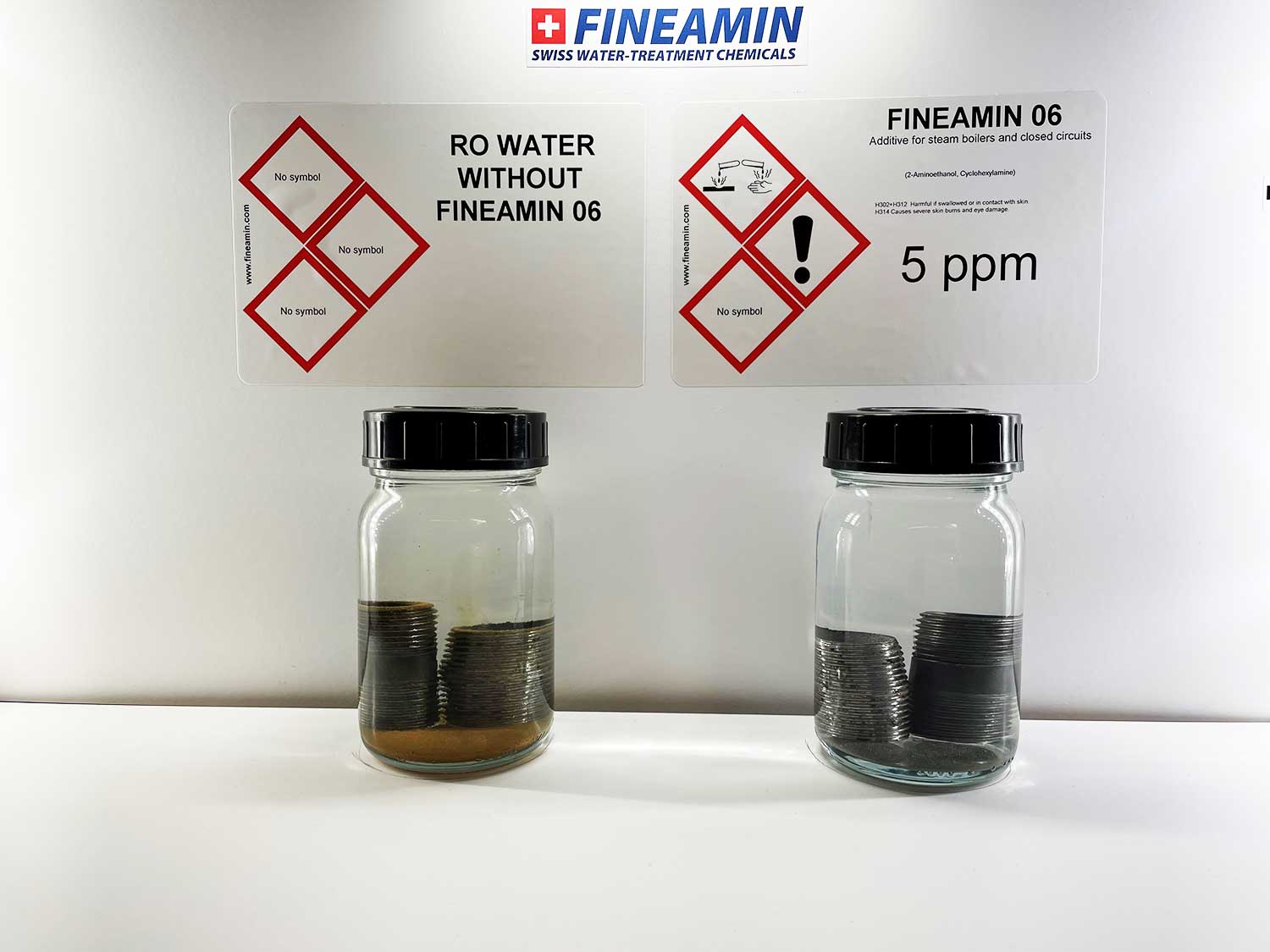

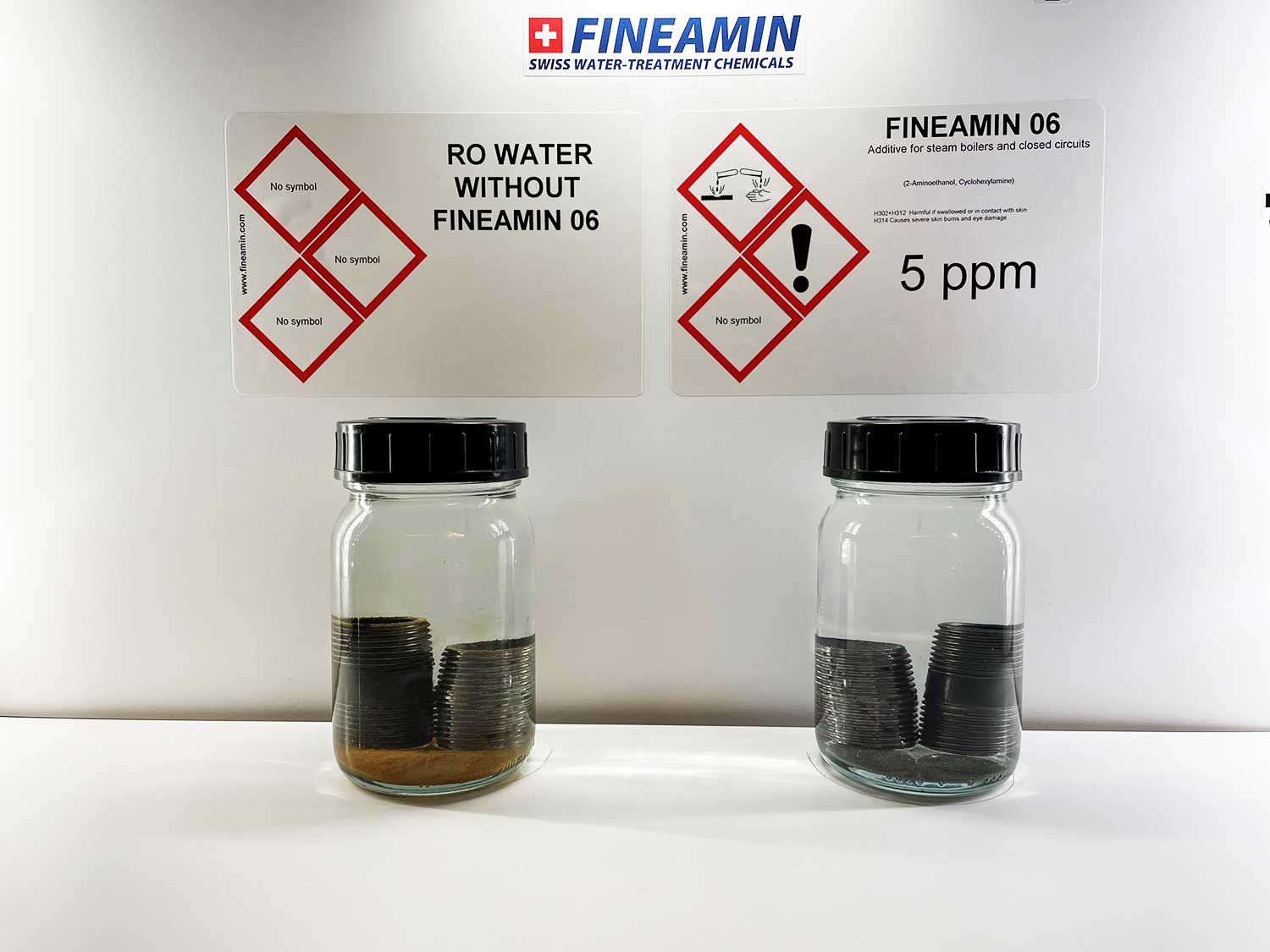

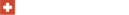

The pictures taken during the 14-days trial show significant differences from one day to the next.

SAMPLE 1

The sample shows the effects of an accelerated corrosion process throughout the whole trial period. After only 24 hours, the water becomes slightly cloudy, with a yellowish coloration. The density of the corrosion products increases gradually during the first days generating, by the middle of the second week, a thick, strongly colored and muddy consistence deposits layer on the bottom of the bottle.

In a normally operated system, the absence of a chemical conditioning additive would not only damage the metal, but also limit the heat transfer surfaces because of the generated deposits, decreasing equipment efficiency.

SAMPLE 2

The sample containing identical raw metal pipes sunk in demineralized water, but with an additional 5ppm quantity of FINEAMIN 06, keeps its original properties for the whole period of the trial. The water is clear, colorless and the pipes show no traces of corrosion, as a proof of fast formation, followed by an uninterrupted presence, of a hydrophobic surface. FINEAMIN 06 does not contain any kind of oxygen scavenger.

The test proves that the addition of polyamines and polymers alone is easily limiting the degradation of the metal under the action of dissolved oxygen, even without removing it from the water, while ensuring a longer life and higher efficiency.